What is SlideMoor?

Description of SlideMoor

Product Specifications

1) Slide -‐ The patented Slide is manufactured from 6061-‐ T6 Extruded aluminum, for strength and high resistance to corrosion.

2) Bumper -‐ Extruded, flexible, high-‐molecular polyvinyl chloride will not crack, rot or corrode. Non-‐marring and impervious to ultraviolet rays. Manufactured for durability and strength and is designed for increased protection with increased pressure.

3) Bearing -‐ ⅛" extruded Carilon® lines the interior surfaces of the Slide for frictionless movement, providing high lubricity for smooth travel on the Track.

4) Cleats -‐ 8" injection molded, non-‐corrosive black nylon Cleats come standard with the system. (2 per Slide).

5) Track -‐ 6061-‐ T6 Extruded aluminum I-‐beam. Track lengths available from 8 to 25 feet.

6) Slide Stop Top & Bottom -‐ Prevents Slide from coming off. Top may be replaced with lock.

7) Fasteners -‐ All fasteners are 18.8 marine grade stainless steel.

8) Mounting Hardware is Not Included.

Track Size and Placement

How to determine track placement

1) Determine the LOWEST your rubrail will be at its lowest point.

2) Start the bottom of the track one foot below that point

3) The top of the track will then allow for the most vertical travel with your chosen track length. Standard 8’ track allows for 6’ of vertical travel.

4) If 6’ of vertical travel is not enough, determine how much vertical travel you will need and see below.

How to determine custom track length?

1) Determine the LOWEST your rubrail will be at its lowest point.

2) Start the bottom of the track one foot below that point

3) Determine how much vertical travel you will want and add one foot to the top of that travel.

4) The track length will be 2’ more than the total vertical travel of your boat.

REMEMBER that the track must be supported by your piling for its entire length!

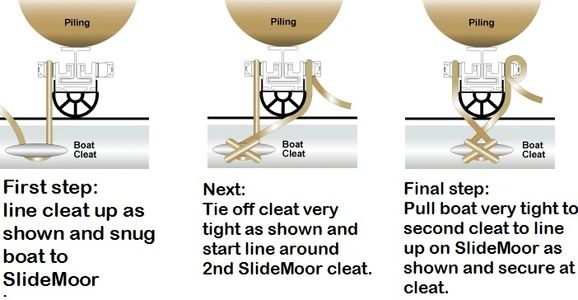

Conditions for Using SlideMoor --- Figure 1.1

It must be said that SlideMoor only works when the boat is held TIGHT to the SlideMoor and will not work any other way!

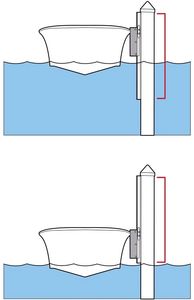

This product is used to control boat location in a slip where tide or water level is prone to change.

On smaller boats it can be used to control boats in wavy conditions along with tide changes.

Since SlideMoor only works when the boat is held TIGHT to the SlideMoor, the location of your piling/track with regard to the cleats on your boat will be your most important consideration. By holding the boat tight, all lines will be on ONE side of the boat with no need for any lines other than the line you use on the SlideMoor. You may need to add a cleat to your boat directly in line with the piling/track OR add or move a piling to be directly in line with the cleat on your boat. The time and expense to do this correctly will be rewarded with the many benefits of the SlideMoor system.

At times unnecessary pilings can be removed from one side of your mooring as is the case with outer pilings. These pilings can be used to correct the line-up problems stated above. This also gives more room to maneuver in your docking area when these pilings are out of the way.

If adding a cleat to your boat, be sure it is attached properly. If your are not sure how to attach a cleat, have it done by a qualified technician.

The ONLY way SlideMoor works is when it is TIGHT!

When typing up your boat to the SlideMoor Boat Docking system the lines need to be tight.

The best method we have seen to get it tight is shown in diagram to left.

Please Note: That each SlideMoor has TWO lines to add to the protection of your boat.

How SlideMoor Works

SlideMoor works much the same as a floating dock.

SlideMoor secures your boat tight with two lines on one side only, eliminating bumping, banging, and other damaging movements.

SlideMoor allows your boat to move securely up and down through waves, wind, and tides.